Dissolving Pulp; Create Cellulosic Substances Such As Acetate And Others

|

| Dissolving Pulp |

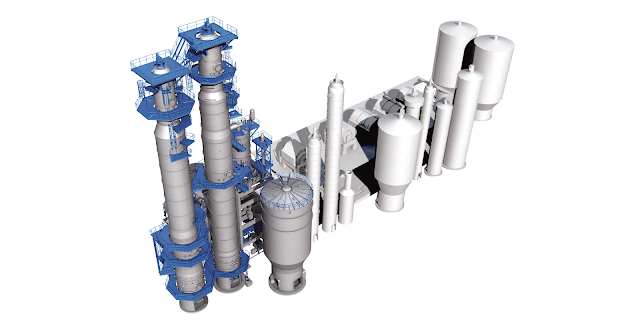

Dissolving Pulp is faded wood pulp or cotton linters with a heavy cellulose mixture that is utilized in downstream viscose-associated procedures. It is also a main raw material for generating cellulose acetate and other special goods. The most general pulping process for dissolving pulp are acid sulfite and prehydrolysis kraft. The procedures boil the plant fibers in pungent chemicals to change the wood chips into fiber that can be utilized to create other cellulose-based goods.

In Acid

Sulfite, the wood is immersed in concentrated sodium hydroxide to dissolve the

lignin, which reduces the hemicellulose and decrease the potential of fiber. It

is further cured with gaseous carbon disulfide to create xanthate substituents

into the low crystal like pieces of the cellulose microfibrils. A main limitation

in the creation of Dissolving

Pulp is build-up of scale, resulting downtime and

procedure erraticism.

Valmet’s

cooking methods have ideal properties that can aid decrease scale, which refers

to less interruption and more consistent outputs for the fiber line. Cellulose

purity is a main reason in the standard of the dissolving pulp. For instance,

high-purity Dissolving Pulp has a roughage

content of 90 % or more. It is also essential to have an equal molecular weight

distribution and polydispersity index for minimal working in interrupted

viscose procedure.

Comments

Post a Comment